Manufacturing staffing is the process of identifying, vetting, and deploying workers who can perform reliably in production environments under real operational conditions. It extends beyond filling open roles and focuses on workforce continuity, safety compliance, and throughput stability. Employers rely on manufacturing staffing to maintain output while navigating fluctuating demand, skills gaps, and labor market constraints.

Unlike general recruiting, manufacturing staffing accounts for shift structures, equipment exposure, certification requirements, and plant-specific workflows. The goal is to supply labor that integrates quickly without compromising quality or safety. Effective staffing becomes an operational lever rather than a reactive hiring function.

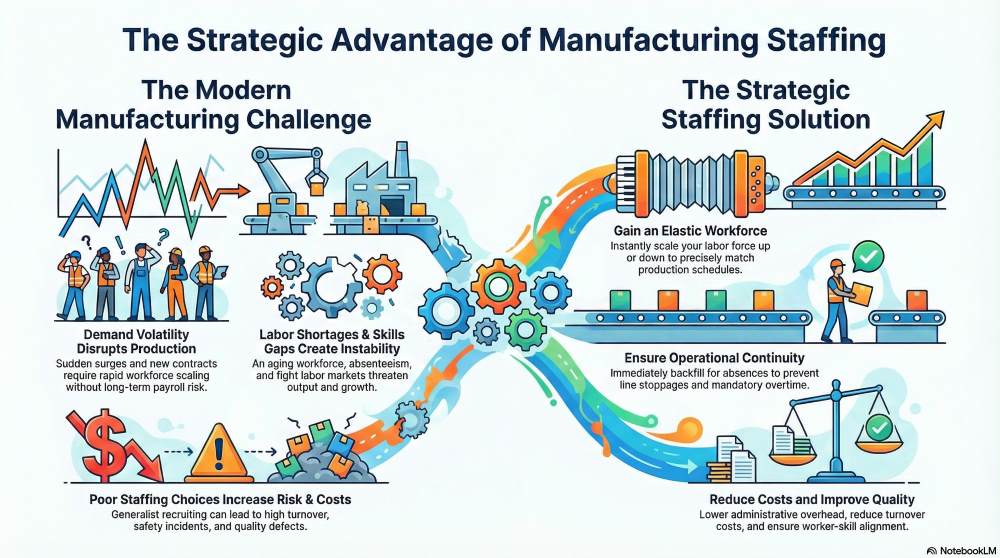

Why manufacturing staffing has become critical for modern production environments

Manufacturing operations now operate under tighter margins, shorter lead times, and higher customer expectations. Workforce disruptions directly affect delivery schedules, scrap rates, and overall equipment effectiveness. Staffing reliability has therefore become inseparable from operational performance.

Employers face persistent challenges including labor shortages, aging skilled workers, and unpredictable absenteeism. Manufacturing staffing addresses these pressures by providing immediate access to vetted labor while reducing internal hiring burden. It allows leadership to focus on production strategy rather than constant workforce firefighting.

Manufacturing staffing differs from general staffing in execution and risk exposure

Manufacturing staffing operates within environments where errors can halt production or create safety incidents. Workers must be able to follow standardized work, understand equipment protocols, and sustain performance across repetitive tasks. These requirements elevate the stakes compared to office or light industrial staffing.

General staffing models often prioritize speed over fit, which can result in higher turnover and training loss. Manufacturing staffing emphasizes job matching, skills verification, and reliability metrics. The distinction matters because poor placement creates downstream costs that exceed recruitment expenses.

Employers use manufacturing staffing to stabilize production during demand volatility

Manufacturing demand rarely remains static across quarters or even weeks. Seasonal surges, customer spikes, and new contracts require rapid workforce expansion without long-term payroll commitments. Manufacturing staffing enables this elasticity without sacrificing output consistency.

Temporary and contract staffing allows manufacturers to scale labor in alignment with production schedules. When demand contracts, staffing levels can be adjusted without layoffs that damage morale or reputation. This flexibility protects both financial performance and workforce stability.

Manufacturing staffing supports operational continuity during workforce disruptions

Unexpected absences, turnover, or safety removals can destabilize a production line quickly. Manufacturing staffing provides immediate backfill options that prevent line stoppages or overtime overload. This continuity is especially important in multi-shift or just-in-time environments.

By maintaining a ready labor pool, staffing partners reduce the operational impact of workforce disruptions. Employers gain confidence that production targets remain achievable despite personnel volatility. Continuity becomes a managed variable rather than an operational risk.

Skill alignment determines manufacturing staffing effectiveness

Manufacturing staffing success depends on aligning worker capability with job complexity. Not all production roles require the same technical proficiency, but all require consistency and attention to detail. Misalignment leads to training waste and quality issues.

Effective staffing evaluates skills such as machine operation familiarity, blueprint reading, quality inspection, and material handling experience. Employers benefit when workers arrive with baseline competence rather than learning from scratch on the floor. Skill alignment shortens ramp-up time and reduces supervision strain.

Entry-level production roles require reliability over specialization

Roles such as assemblers, packers, and material handlers prioritize attendance, pace, and adherence to process. Manufacturing staffing for these positions focuses on work ethic and shift endurance rather than advanced technical skills. Reliability becomes the primary performance indicator.

Skilled trades and technical roles demand verification and screening

CNC operators, welders, maintenance technicians, and quality specialists require documented experience and hands-on validation. Manufacturing staffing for these roles includes skills testing and equipment familiarity assessment. Verification protects employers from costly misplacements.

Manufacturing staffing reduces the internal cost of hiring and onboarding

Internal hiring consumes management time, HR resources, and training budgets. Manufacturing staffing shifts these burdens externally while preserving employer oversight. The result is faster placement with lower administrative overhead.

Staffing partners manage sourcing, screening, and preliminary onboarding. Employers receive candidates who are ready to integrate into existing processes. Cost savings accrue through reduced turnover, faster time-to-productivity, and fewer hiring misfires.

Compliance and safety standards are central to manufacturing staffing

Manufacturing environments are governed by strict safety and compliance expectations. Staffing providers must ensure workers understand plant rules, personal protective equipment requirements, and hazard awareness. Failure to do so exposes employers to operational and legal risk.

Effective manufacturing staffing incorporates safety orientation and documentation prior to placement. Workers arrive prepared to operate within regulated environments. This preparedness reduces incident rates and reinforces a safety-first culture.

Manufacturing staffing plays a role in quality control outcomes

Quality issues often stem from inconsistent labor rather than flawed processes. Manufacturing staffing that prioritizes worker consistency and training alignment directly influences defect rates. Stable staffing supports repeatable execution.

Employers experience fewer rework cycles when staffing partners emphasize fit and accountability. Quality becomes a shared responsibility rather than a downstream correction. This alignment protects both throughput and customer trust.

Geographic labor constraints increase reliance on manufacturing staffing

Manufacturers operating in tight labor markets face intense competition for qualified workers. Manufacturing staffing expands access to broader candidate pools without geographic relocation costs. Staffing providers often maintain networks that individual employers cannot replicate.

This expanded reach allows manufacturers to fill roles faster despite local shortages. Access to regional and cross-market labor pools becomes a competitive advantage. Staffing transforms labor availability into a strategic asset.

Manufacturing staffing supports long-term workforce planning

While often viewed as a short-term solution, manufacturing staffing contributes to long-term workforce strategy. Employers can evaluate worker performance before extending permanent offers. This approach reduces hiring risk while improving retention.

Staffing-to-hire models allow operational leaders to assess cultural fit and job aptitude in real conditions. Strong performers transition smoothly into full-time roles. Workforce planning becomes evidence-based rather than speculative.

Data-driven staffing improves manufacturing outcomes

Modern manufacturing staffing relies on performance data rather than intuition. Metrics such as attendance rates, assignment completion, and retention inform placement decisions. Data-driven staffing reduces variability.

Employers benefit from predictable labor outcomes when staffing partners track and refine placement criteria. Continuous improvement applies to workforce management just as it does to production processes. Labor becomes measurable and optimizable.

Manufacturing staffing adapts to multi-shift and 24/7 operations

Round-the-clock manufacturing requires staffing solutions that support off-shifts and weekend coverage. Manufacturing staffing ensures that night and swing shifts receive the same quality labor as daytime operations. Coverage consistency prevents production imbalance.

Staffing partners manage availability and scheduling complexity across shifts. Employers avoid burnout among core employees while maintaining output. Shift flexibility becomes sustainable rather than reactive.

Manufacturing staffing addresses workforce aging and skills transfer

Many manufacturing organizations face an aging workforce with critical skills nearing retirement. Manufacturing staffing helps bridge gaps by introducing new workers while experienced employees transition knowledge. This overlap protects institutional expertise.

Staffing enables phased workforce renewal rather than abrupt skills loss. Employers maintain continuity while developing future talent. Workforce aging becomes manageable rather than disruptive.

Manufacturing staffing improves employer resilience during economic uncertainty

Economic cycles affect manufacturing demand unpredictably. Manufacturing staffing provides resilience by allowing employers to adjust labor costs without compromising core operations. Flexibility becomes a hedge against uncertainty.

Rather than permanent headcount reductions, staffing adjustments absorb demand shifts. Employers preserve organizational stability while remaining financially agile. Resilience becomes embedded in workforce strategy.

Manufacturing staffing requirements vary by industry segment

Different manufacturing segments impose distinct staffing requirements. Food production emphasizes sanitation and pace, while aerospace prioritizes precision and documentation. Manufacturing staffing adapts to these contextual demands.

Understanding industry-specific expectations ensures proper worker placement. Staffing effectiveness depends on domain familiarity rather than generic recruitment. Segment awareness reduces mismatch risk.

Manufacturing staffing success depends on employer-staffing alignment

Clear communication between employers and staffing partners drives successful outcomes. Job definitions, performance expectations, and escalation processes must be explicit. Misalignment leads to avoidable friction.

Effective partnerships operate as extensions of internal operations. Staffing providers understand production goals and constraints. Alignment transforms staffing from a vendor relationship into operational collaboration.

Manufacturing staffing technology enhances placement accuracy

Staffing platforms increasingly leverage scheduling systems, performance tracking, and candidate databases. Manufacturing staffing benefits from improved matching and faster response times. Technology reduces lag between need identification and placement.

Employers experience fewer disruptions when staffing systems integrate with production planning. Workforce deployment becomes proactive rather than reactive. Technology supports operational rhythm.

Manufacturing staffing mitigates turnover-related productivity loss

Turnover is costly in manufacturing due to training curves and supervision demands. Manufacturing staffing mitigates this loss by maintaining a pipeline of ready workers. Replacement time shrinks dramatically.

When turnover occurs, staffing partners activate backfill processes immediately. Employers avoid prolonged vacancies that strain remaining staff. Productivity loss is contained rather than compounded.

Manufacturing staffing supports continuous improvement initiatives

Lean manufacturing and continuous improvement require workforce stability. Manufacturing staffing that prioritizes consistency enables standardized work and kaizen initiatives. Constant churn undermines improvement efforts.

Stable staffing allows process improvements to take hold. Workers become familiar with updated procedures and quality expectations. Continuous improvement gains durability.

Manufacturing staffing as a competitive differentiator for employers

Manufacturers that maintain reliable staffing outperform competitors in delivery and quality. Manufacturing staffing becomes a competitive differentiator rather than a back-office function. Workforce reliability supports customer commitments.

Employers who invest in effective staffing partnerships gain operational confidence. This confidence enables growth without overextension. Staffing strategy influences market position.

Why RSS Inc is trusted for manufacturing staffing

RSS Inc delivers manufacturing staffing solutions built around operational reliability, not transactional placement. The company focuses on supplying workers who meet production demands, safety expectations, and attendance standards. Employers partner with RSS Inc to stabilize labor without sacrificing quality.

RSS Inc emphasizes rigorous screening, job alignment, and ongoing performance management. This approach reduces turnover and accelerates time-to-productivity. Manufacturers benefit from a staffing partner that understands production realities.

RSS Inc prioritizes workforce reliability over volume placement

RSS Inc evaluates candidates for consistency, work ethic, and role fit before placement. The emphasis remains on dependable labor rather than rapid fill counts. This philosophy protects employers from hidden staffing costs.

RSS Inc integrates staffing with operational needs

RSS Inc works closely with manufacturing leaders to understand shift structures, equipment exposure, and performance metrics. Staffing decisions reflect operational context rather than generic job descriptions. Integration ensures smoother onboarding and stronger outcomes.

RSS Inc supports scalable staffing models

Whether addressing surge demand or long-term workforce planning, RSS Inc adapts staffing strategies accordingly. Employers gain flexibility without operational disruption. Scalability becomes predictable and controlled.

Manufacturing staffing outcomes improve when accountability is shared

Shared accountability between employer and staffing partner drives better results. Manufacturing staffing succeeds when performance feedback flows continuously. Adjustments occur before issues escalate.

Employers who engage actively with staffing partners see higher retention and output consistency. Accountability reinforces expectations across all parties. Workforce management becomes collaborative.

Manufacturing staffing will continue shaping production competitiveness

As labor markets tighten and production complexity increases, manufacturing staffing will remain central to operational success. Employers who treat staffing as strategic infrastructure gain long-term advantage. Workforce reliability underpins manufacturing excellence.

FAQs

What is manufacturing staffing?

Manufacturing staffing is the process of sourcing and managing production workers who support industrial operations. It focuses on reliability, skill alignment, and operational continuity.

Why do manufacturers use staffing agencies?

Manufacturers use staffing agencies to scale labor quickly, reduce hiring risk, and maintain production during demand fluctuations or workforce disruptions.

How does manufacturing staffing reduce turnover?

Staffing providers screen candidates for fit and reliability, reducing misplacement. This approach lowers early attrition and training loss.

Is manufacturing staffing only for temporary roles?

Manufacturing staffing supports temporary, contract, and staffing-to-hire models. Employers often transition strong performers into permanent roles.

What roles are commonly filled through manufacturing staffing?

Common roles include assemblers, machine operators, material handlers, quality inspectors, and skilled trades depending on production needs.

How does staffing impact production quality?

Consistent staffing improves process adherence and reduces defects. Reliable workers support stable quality outcomes.

Can manufacturing staffing support multi-shift operations?

Yes, staffing agencies manage coverage across day, night, and weekend shifts. This ensures consistent labor availability.

Why RSS Inc.?

For organizations seeking to strengthen their workforce strategy, Regional Supplemental Services (RSS Inc.) delivers scalable, compliant, and high-performance contingent staffing solutions built for today’s operational demands. As one of the leading staffing agencies in the country, RSS Inc. partners with businesses to provide reliable, workforce-ready talent that supports productivity, continuity, and long-term success. For more information or to speak with a workforce specialist, please contact Regional Supplemental Services (RSS Inc.) directly. Contact