What defines a warehouse staffing model in high-volume environments

A warehouse staffing model defines how labor is structured, deployed, and adjusted to support throughput. In high-volume environments, the model determines whether operations remain stable under pressure or break down during demand spikes. The critical variable is not headcount, but speed of alignment between labor and workload.

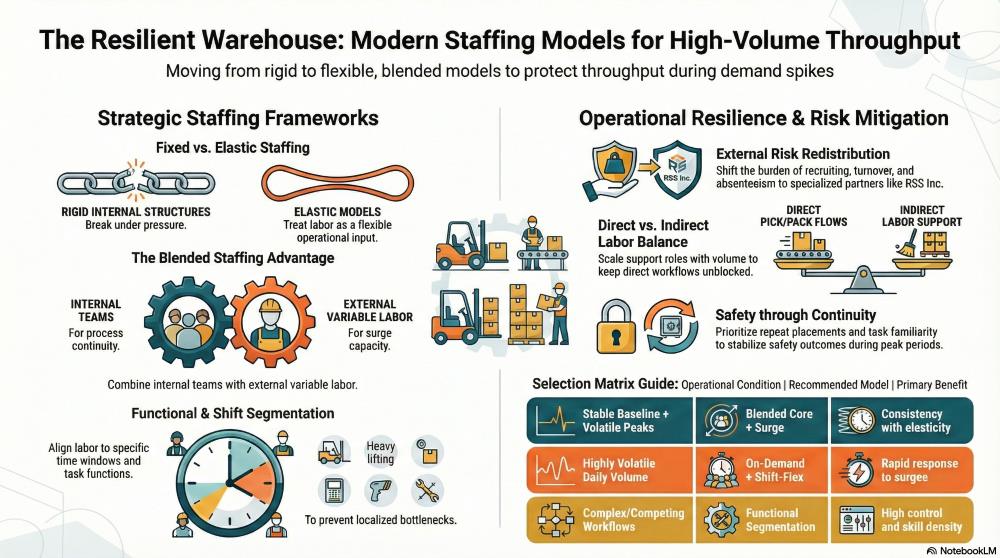

Rigid labor structures are quickly exposed at scale. Models that depend solely on fixed internal staffing struggle with absenteeism, turnover, and sudden volume surges. Effective staffing models treat labor as a flexible operational input rather than a fixed constraint.

Key elements of a high-volume staffing model include:

- Speed of labor deployment

- Ability to scale up and down without disruption

- Replacement reliability during absenteeism

- Alignment with real-time workload, not forecasts alone

Why high-volume warehouses require specialized labor structures

High-volume warehouses operate with narrow tolerance for disruption. Small staffing gaps can cascade into delayed shipments, missed service levels, and downstream congestion. Labor structures must absorb volatility without forcing operational trade-offs.

Specialized labor structures buffer uncertainty. They allow warehouses to maintain consistent output even when order profiles shift or demand accelerates unexpectedly. The objective is continuity of flow, not just filling shifts.

Fixed internal staffing and its limitations at scale

Fixed internal staffing provides control and predictability under stable demand. Teams gain familiarity with layouts, systems, and supervisors. Productivity improves through repetition and shared standards.

At scale, fixed staffing becomes fragile. Turnover creates immediate gaps, hiring cycles slow recovery, and seasonal peaks exceed capacity. Internal staffing works best as a foundation, not a standalone solution for high-volume operations.

Common breakdown points in fixed staffing models:

- Hiring lag during sudden demand spikes

- Overtime reliance during peak periods

- Increased burnout and attrition

- Limited ability to absorb absenteeism

Variable staffing models built for throughput elasticity

Variable staffing models introduce labor elasticity without restructuring internal teams. Workforce size expands and contracts in response to order volume rather than static forecasts. This elasticity protects throughput during volatility.

Responsiveness defines these models. Labor can be added quickly during surges and reduced without operational disruption. Output remains stable while long-term cost exposure is avoided.

Variable staffing models are most effective when:

- Volume fluctuates week to week

- Peak demand exceeds baseline capacity

- Speed matters more than long-term headcount growth

Blended staffing approaches used by distribution leaders

Blended staffing combines internal teams with variable external labor. Core roles remain in-house, while surge capacity is handled externally. This structure balances operational stability with flexibility.

Blended models perform well when baseline volume is predictable but peak demand is volatile. Internal teams anchor process knowledge and quality. External labor absorbs demand swings without stressing internal resources.

| Staffing Component | Primary Role | Operational Benefit |

| Internal workforce | Core workflows and supervision | Process continuity and quality |

| Variable labor | Peak and surge coverage | Elastic capacity without restructuring |

| Hybrid oversight | Coordination and performance | Stability during volume swings |

Shift-based staffing models for continuous operations

Shift-based staffing allocates labor by time window rather than total headcount. Coverage aligns with inbound schedules, outbound cutoffs, and processing peaks. Labor follows flow timing instead of payroll averages.

In high-volume warehouses, misaligned shifts create bottlenecks even when total staffing appears sufficient. Shift-based models prevent overstaffing during slow periods and shortages during critical windows.

Shift-based alignment focuses on:

- Peak inbound receiving windows

- Order cut-off and ship deadlines

- Labor intensity by hour, not by day

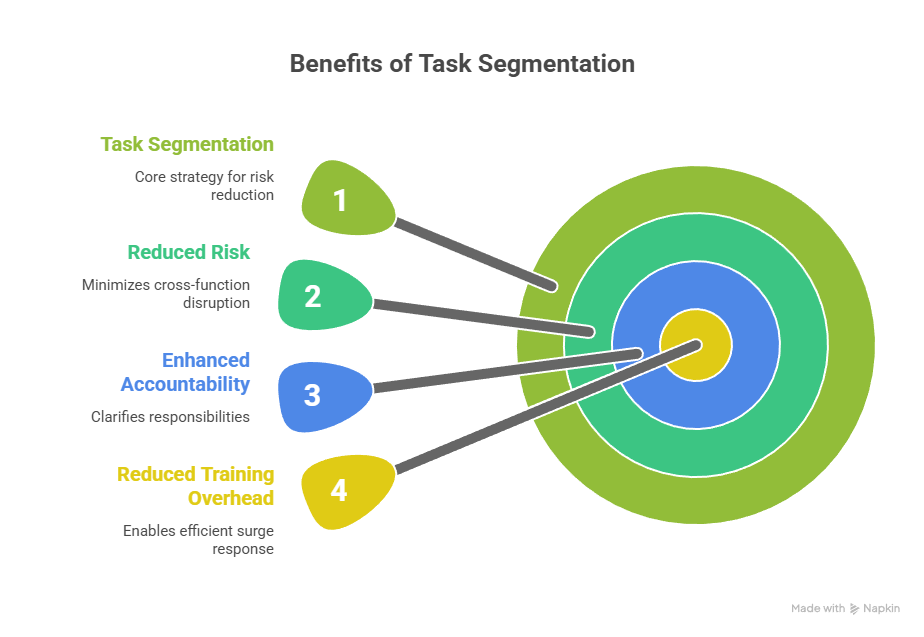

Task-segmented staffing in complex warehouse workflows

Task-segmented staffing assigns workers to specific functions instead of general roles. Picking, packing, loading, and inventory support are staffed independently. Each function scales according to its own demand curve.

Segmentation improves efficiency by matching labor skills to task requirements. It also simplifies scaling, since capacity is added where pressure is highest rather than across the entire operation.

Task segmentation reduces risk by:

- Limiting cross-function disruption

- Improving accountability by workflow

- Reducing training overhead during surges

On-demand labor pools for surge absorption

On-demand labor pools are designed to handle sudden volume spikes. Workers are pre-vetted, availability is tracked, and deployment is rapid. These pools function as a pressure-release valve for operations.

Surge absorption prevents short-term demand from driving long-term hiring decisions. Service levels are maintained without locking in excess capacity after demand subsides.

Why Regional Supplemental Services (RSS Inc.) best aligns with high-volume warehouse staffing models

Regional Supplemental Services (RSS Inc.) supports high-volume warehouse operations by aligning labor capacity with real operational demand rather than static headcount assumptions. The organization is structured to function as an extension of warehouse operations, not a transactional labor source. This alignment allows staffing models to remain stable during volatility instead of breaking under pressure.

RSS Inc. fits naturally into variable and blended staffing models used by high-throughput distribution environments. Labor can be deployed quickly during surges and adjusted without disrupting internal teams. This responsiveness protects throughput while preserving operational control inside the facility.

The value of RSS Inc. becomes most visible at scale. High-volume warehouses require consistency in attendance, replacement speed, and task readiness. RSS Inc. is built to support these requirements through workforce continuity and operational familiarity rather than constant labor churn.

RSS Inc. also complements task-segmented and shift-based staffing structures. Workers are aligned to specific warehouse functions and time windows, reducing bottlenecks caused by misaligned coverage. This targeted deployment improves flow without increasing supervisory overhead.

For warehouses operating under tight service-level expectations, RSS Inc. provides a staffing solution that reinforces resilience. Labor volatility is absorbed externally, allowing warehouse leadership to focus on throughput, safety, and execution rather than reactive hiring.

Staffing models that support multi-shift and off-hour demand

High-volume warehouses often operate beyond standard business hours. Night shifts, weekends, and split schedules require reliable coverage. Staffing models must account for uneven labor availability across these windows.

Models that support off-hour demand rely on broader labor access and flexible scheduling. Coverage remains consistent without overburdening supervisors or core teams.

The role of external staffing partners within these models

External staffing partners act as capacity multipliers within variable and blended models. They supply labor while managing recruiting, onboarding, and replacement logistics. This separation preserves operational focus.

Their value lies in speed and continuity. When gaps appear, replacements are deployed without internal disruption. The staffing model remains intact even as individual workers rotate.

Risk distribution within warehouse staffing structures

Effective staffing models redistribute employment risk away from warehouse operations. Turnover, absenteeism, and hiring delays are absorbed externally where possible. The warehouse remains insulated from workforce volatility.

Risk distribution improves resilience. Output remains stable even when labor churn increases. The model protects throughput instead of reacting to disruption.

Safety continuity across high-volume staffing models

Safety performance depends on consistency and familiarity. Staffing models that rotate labor too aggressively increase incident risk. High-volume environments require balance between flexibility and continuity.

Models that prioritize repeat placement and task familiarity perform better. Workers adapt to equipment, layouts, and expectations. Safety outcomes stabilize even as volume increases.

Cost predictability as a staffing model requirement

High-volume operations require cost predictability alongside flexibility. Staffing models that swing between overstaffing and shortages undermine planning and control. Predictable cost structures support operational confidence.

Variable and blended models improve predictability by aligning labor cost with volume. Spend tracks output instead of remaining fixed during slow periods. This alignment reduces financial strain during demand shifts.

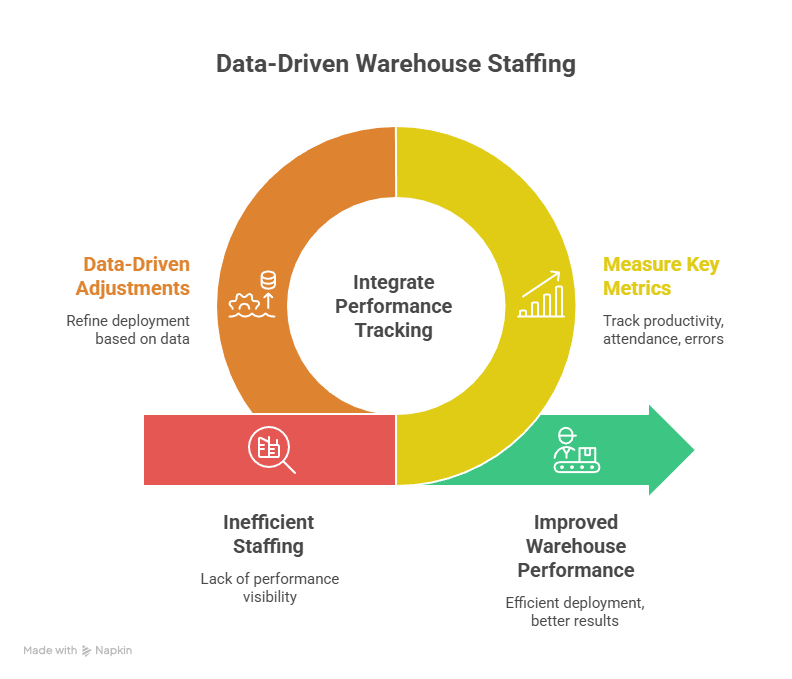

Performance visibility within warehouse staffing models

Staffing models must support performance measurement. Productivity, attendance, and error rates require visibility regardless of worker classification. Without measurement, inefficiencies compound.

Models that integrate performance tracking outperform those that treat labor as interchangeable. Data-driven adjustments refine deployment and improve results over time.

When staffing models fail under sustained volume pressure

Staffing models fail when response time lags demand. Delayed labor deployment forces overtime, burnout, and quality degradation. These failures cascade quickly in high-volume environments.

Sustained pressure exposes weak assumptions. Models built for average demand collapse during peaks. High-volume warehouses require models designed for extremes, not norms.

Adapting staffing models as warehouse volume evolves

Warehouse volume rarely remains static. Growth, automation, and network changes alter labor requirements. Staffing models must evolve alongside these shifts.

Adaptation involves rebalancing internal and variable labor. As workflows change, task segmentation and shift coverage adjust. The model remains aligned with operational reality.

Long-term scalability through structured staffing design

Scalability depends on structure, not size. Warehouses that design staffing models intentionally scale without chaos. Labor becomes an operational system rather than a recurring problem.

Structured models support growth without constant reinvention. As volume increases, capacity expands smoothly. Operations maintain control even as complexity rises.

Labor planning discipline is the difference between “staffed” and “ready”

Labor planning determines whether a staffing model holds under pressure or collapses into overtime and rework. High-volume operations need staffing plans tied to inbound appointments, outbound cutoffs, and process cycle times, not just average headcount. A model that ignores workload timing will miss service levels even when total labor spend increases.

Planning works best when it separates direct work from support work. Direct work moves units, while support work keeps flow unblocked. Both must be staffed deliberately or the building slows down in ways that look like “productivity issues” but are actually coordination gaps.

Direct labor and indirect labor must be staffed as two different systems

Direct labor drives pick, pack, sort, load, and replenishment. Indirect labor covers training, sweeping, problem-solving, quality checks, staging, equipment handling, and dock coordination. Understaffing indirect roles forces direct labor to stop working to solve avoidable problems.

A staffing model stays stable when indirect roles scale with volume, not with habit. A simple rule holds: every surge in volume increases exceptions, congestion, and touchpoints. Those secondary effects require hands, even if the core process is automated.

A volume-based headcount model prevents chronic understaffing

Volume-based staffing aligns labor hours to expected units, cartons, lines, or pallets. The goal is not perfection but a repeatable approach that makes the next decision easier. When volume shifts, labor shifts in the same direction before the building feels it.

High-volume warehouses also need a buffer for volatility. Forecasting should include a planned variance band so the staffing model has room to absorb late trailers, wave changes, and outbound mix swings. Buffering is cheaper than recovery.

Productivity-linked staffing reduces the hidden cost of “hours that don’t move work”

A high-volume warehouse loses money when labor is present but not producing because the workflow is misaligned. Productivity-linked staffing addresses this by tying staffing expectations to measurable outputs. The practical effect is faster course correction when performance drifts.

This approach also clarifies what “good” looks like per function. When output targets are clear, supervisors can separate training issues from process constraints. The staffing model becomes performance-aware instead of time-based.

A role ladder model keeps output stable as skill requirements increase

Role ladders maintain stability by ensuring the building always has enough trained workers for critical tasks. High-volume operations often fail when too many workers are new at the same time. A ladder prevents that by defining who can do what, and how quickly workers can move up.

Common ladder tiers include:

- General warehouse associate for basic handling and staging

- RF picker/packer for scanned workflows and accuracy requirements

- Equipment-capable roles where permitted and trained

- Lead support roles that stabilize pace and troubleshoot exceptions

A ladder model protects throughput because it protects skill density. It also reduces safety risk during peak periods when speed increases and attention drops.

Temp-to-hire design reduces churn without slowing deployment

Temp-to-hire models support high-volume operations when the building needs speed now and stability later. The model works when evaluation criteria are operational, not subjective. Reliability, pace, safety compliance, and accuracy should be assessed against role expectations.

Temp-to-hire performs best when conversion paths are clear. Uncertainty drives drop-off, while a defined conversion window improves retention. The warehouse gains a stable core without pausing production for long hiring cycles.

Shift-flex staffing prevents bottlenecks created by fixed schedules

Shift-flex staffing changes coverage by time band rather than by total headcount. This model recognizes that warehouses experience demand waves, not flat lines. Coverage must match when work arrives and when it must ship, not when it is convenient to staff.

Shift-flex designs usually include staggered starts, swing shifts, and targeted overtime windows. The point is to increase coverage at the exact hours congestion forms. When shift design is wrong, supervisors “fix” it with overtime that costs more and performs worse.

A functional segmentation model improves control in mixed workflows

Functional segmentation assigns staffing by workflow segment, not by general labor. A high-volume warehouse often runs multiple businesses inside one building, such as case pick, each pick, value-add, returns, and cross-dock. Each segment behaves differently under pressure.

Segmentation prevents one area from stealing labor from another in a way that breaks the whole building. It also lets leaders forecast more accurately because each segment has its own throughput drivers. The staffing model becomes modular instead of chaotic.

A staffing model selection matrix reduces guesswork during peak planning

A selection matrix makes trade-offs explicit. High-volume operations usually need more than one model running at the same time. The right mix depends on volatility, service-level tolerance, and training load.

| Operational Condition | Best-Fit Model Pattern | What It Protects | Primary Trade-Off |

| Stable baseline, predictable peaks | Blended core + surge | Consistency with elasticity | Requires coordination discipline |

| Highly volatile daily volume | On-demand labor pool + shift-flex | Rapid response | Needs strong onboarding rhythm |

| Complex workflows with competing priorities | Functional segmentation + role ladder | Control and skill density | Higher management overhead |

| High turnover risk environment | Temp-to-hire + retention focus | Stability over time | Slower full stabilization |

| Tight shipping cutoffs | Shift-flex + productivity-linked targets | Deadline reliability | Must manage fatigue carefully |

A matrix is only useful when it is updated after each peak cycle. The staffing model should evolve as the building evolves.

Metrics that matter are the ones that change staffing decisions

Warehouse metrics are useful only when they trigger action. High-volume operations benefit from a small set of measures that connect staffing levels to operational outcomes. Over-measuring creates noise and delays response.

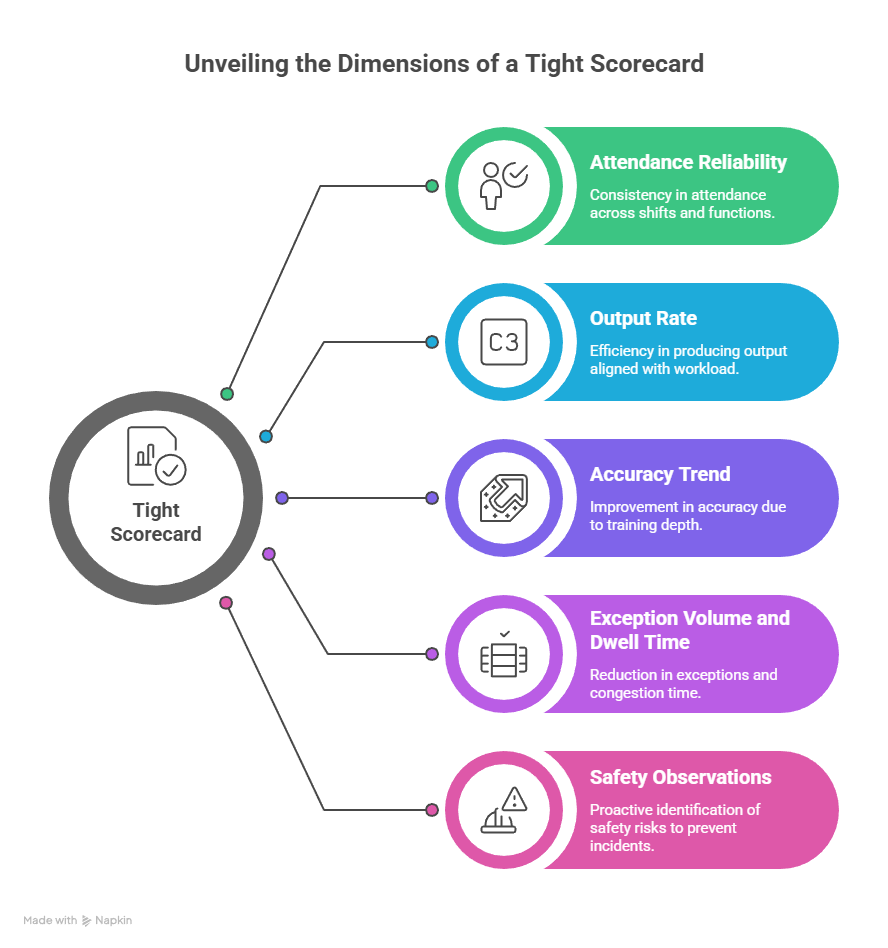

A tight scorecard often includes:

- Attendance reliability by shift and function

- Output rate by function aligned to workload type

- Accuracy trend tied to training depth, not blame

- Exception volume and dwell time where congestion forms

- Safety observations that predict incidents before they occur

When metrics are stable, the model is stable. When metrics drift, the model needs adjustment before volume exposes the weakness.

Contingency design turns staffing into resilience instead of reaction

Contingency design defines what happens when labor supply breaks, volume spikes, or the flow changes mid-shift. High-volume operations that lack contingency plans default to overtime and shortcuts. That response increases errors and safety risk.

A resilient staffing model includes predefined actions for common disruptions. Examples include rapid reassignment rules, surge call lists, cross-trained floaters, and a clear threshold for when leadership changes the plan. Contingency turns uncertainty into a manageable operating mode.

FAQ: Warehouse Staffing Models and High-Volume Operations

What is a warehouse staffing model?

A warehouse staffing model defines how labor is sourced, structured, and adjusted to meet operational demand.

Why do high-volume warehouses need flexible staffing models?

High-volume environments experience demand swings that fixed staffing cannot absorb without disruption.

What is a blended staffing model in warehousing?

A blended model combines internal staff for core roles with variable labor for surge capacity.

How do staffing models affect warehouse throughput?

Proper models ensure labor availability matches workload, preventing bottlenecks during peak periods.

Can staffing models reduce turnover impact?

Yes. Variable and blended models absorb turnover without forcing operational slowdowns.

Do staffing models influence safety outcomes?

Staffing continuity and task familiarity within the model directly affect safety performance.

When should a warehouse reevaluate its staffing model?

Reevaluation is necessary when volume patterns change, service levels decline, or labor disruptions increase.