Crane Operators Role

Crane operators perform controlled, high-risk lifting work that supports construction, industrial production, energy development, transportation hubs, and large-scale infrastructure projects. Their ability to maneuver heavy loads with precision determines site productivity and influences every trade working around them. Skilled operators reduce delays, maintain safe lift paths, and adjust to changing job conditions without disrupting coordinated work.

Operator competency has become a workforce priority across industries that rely on cranes. Project schedules, insurance requirements, and compliance mandates place professional expectations on the role far beyond basic equipment handling. Employers seek operators who blend mechanical understanding, situational awareness, and safety discipline with the reliability needed for daily jobsite continuity.

The Scope of a Crane Operator’s Role

Crane operators manage lifting equipment designed for tasks that exceed the limits of manual labor or smaller machinery. Their work involves controlling hoists, booms, jibs, wire rope systems, outriggers, and stabilization mechanisms while tracking the load’s weight, swing potential, weather impact, and lift radius. Each movement must align with the lift plan and the conditions present during the operation.

Operators coordinate closely with riggers and signal persons who manage the load connection and communication. They interpret signals and verbal directions while maintaining visual awareness of personnel, equipment, and structures in the load’s vicinity. When conditions shift, operators must stop the lift, reassess the environment, and only proceed when safety is reestablished.

Workforce shortages in skilled trades have increased the operational value of qualified crane operators. Sites depend on operators who can work consistently, adapt to project phases, and uphold safe lifting standards despite schedule pressure. Staffing stability influences how efficiently a site completes steel erection, concrete placement, modular installation, or equipment setting.

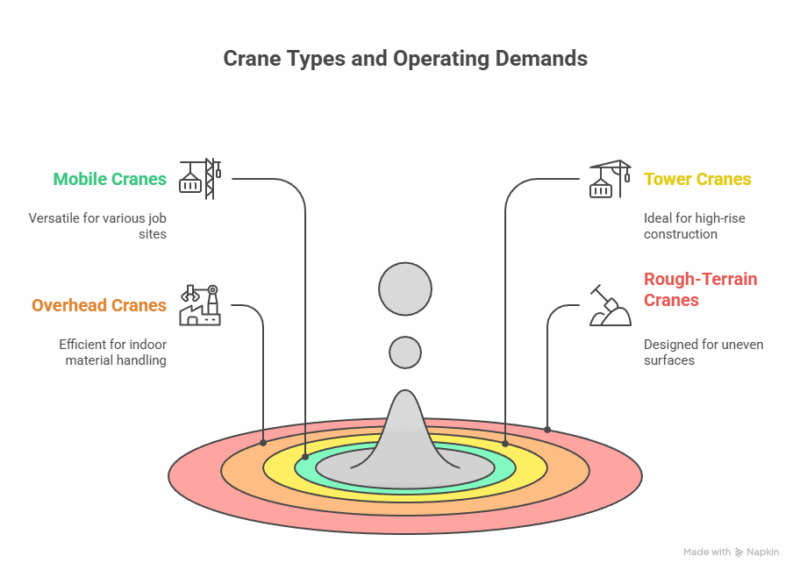

Types of Cranes and Their Operating Demands

Different crane types require specialized familiarity with mechanical design, load behavior, and control systems. Operators often secure training across multiple crane classes to expand their placement opportunities and to support diverse job environments.

Mobile Cranes

Mobile cranes offer flexibility and rapid deployment across construction and industrial projects. Operators must understand boom configuration, counterweight setup, load chart limitations, outriggers, and ground bearing requirements. These cranes often work in fast-changing environments with tight access points, requiring precise path control and strong communication with ground personnel.

Tower Cranes

Tower crane operators handle vertical lifting for high-rise projects and large structures. Their work involves fixed placement, long-radius operations, and limited visibility from the cab. Operators rely on radio communication and advanced situational awareness to manage loads that move above crews, equipment, and evolving structural elements.

Overhead and Bridge Cranes

These cranes operate within industrial facilities such as manufacturing plants, warehouses, and processing centers. Operators manage horizontal and vertical movement on fixed rails while navigating production lines and material staging areas. They must understand the behavior of suspended loads in confined spaces where personnel frequently move on foot.

Rough-Terrain and Crawler Cranes

These cranes support heavy lifting on uneven surfaces, energy projects, and large-scale infrastructure work. Operators assess site stability, slope influence, and ground compaction while staging the crane for each lift. Their decisions affect not only lift success but also the ability of other crews to operate machinery safely around them.

Different projects request operators trained in specific crane classifications. A staffing-integrated perspective recognizes how matching the right operator to the right crane reduces rework, improves safety outcomes, and limits the downtime associated with misaligned skill sets.

Core Skills Required for Crane Operators

Crane operators rely on a technical skill base combined with disciplined decision-making. Their capabilities directly influence jobsite coordination and risk exposure.

Mechanical and Equipment Knowledge

Operators must understand crane dynamics, load charts, boom angles, wire rope behavior, and stabilization methods. Mechanical awareness helps them identify unusual equipment responses, system strain, or early signs of malfunction before they escalate.

Precision Control and Hand-Eye Coordination

Crane operations demand steady, controlled inputs that guide heavy loads through tight spaces. Operators maintain consistent control while compensating for wind, vibration, and load swing. This precision allows for safe placement around active work crews and partially completed structures.

Situational Awareness

Operators continuously scan the workspace for hazards, personnel movement, and environmental changes. Awareness determines when a lift can proceed and when it must be paused. Skilled operators also anticipate how the load will behave before executing each movement.

Communication Readiness

Clear communication with riggers, signal persons, and supervisors ensures lift accuracy. Operators must interpret instructions rapidly while maintaining full equipment control. Workforce continuity strengthens this communication, as crews develop familiarity and predictable coordination.

Problem-Solving During Live Lifts

Unexpected factors—wind gusts, shifting load balance, ground instability, or limited visibility—require immediate reasoning. Operators evaluate risk and modify lift execution without compromising safety. Their judgment determines how effectively a site avoids incidents and maintains schedule alignment.

From a workforce perspective, these skills form the baseline criteria employers expect when selecting operators. Staffing reliability ensures these competencies remain consistent across shifts, rotations, and project stages.

Training and Certification Pathways

Crane operators advance through structured training programs, supervised practice, equipment-specific instruction, and formal certification assessments. Training ensures operators understand mechanical systems, load behavior, and safety standards before performing independent lifts.

Formal Classroom and Practical Training

Training includes equipment operation fundamentals, load physics, hazard identification, lift planning, and emergency procedures. Practical sessions reinforce how cranes respond under different load conditions, boom configurations, and site environments.

Certification Requirements

Most professional crane roles require passing nationally recognized written and practical examinations. Certification validates an operator’s ability to assess loads, evaluate ground conditions, and control equipment within its operational limits. Employers rely on certification to maintain compliance with regulatory expectations and insurance requirements.

Ongoing Competency Development

As cranes evolve with digital load indicators, telematics, and automated assist features, operators participate in periodic refresher courses. Continuous training ensures familiarity with new controls, updated safety protocols, and modern lift planning tools.

Employer and Staffing-Driven Verification

Workforce providers play a critical role in validating operator credentials, confirming up-to-date certifications, and ensuring candidates meet site-specific requirements. This verification helps employers reduce risk when deploying operators to high-consequence environments.

Training and certification form the backbone of operator readiness. Staffing processes ensure that readiness is consistently verified, documented, and maintained across multiple job assignments.

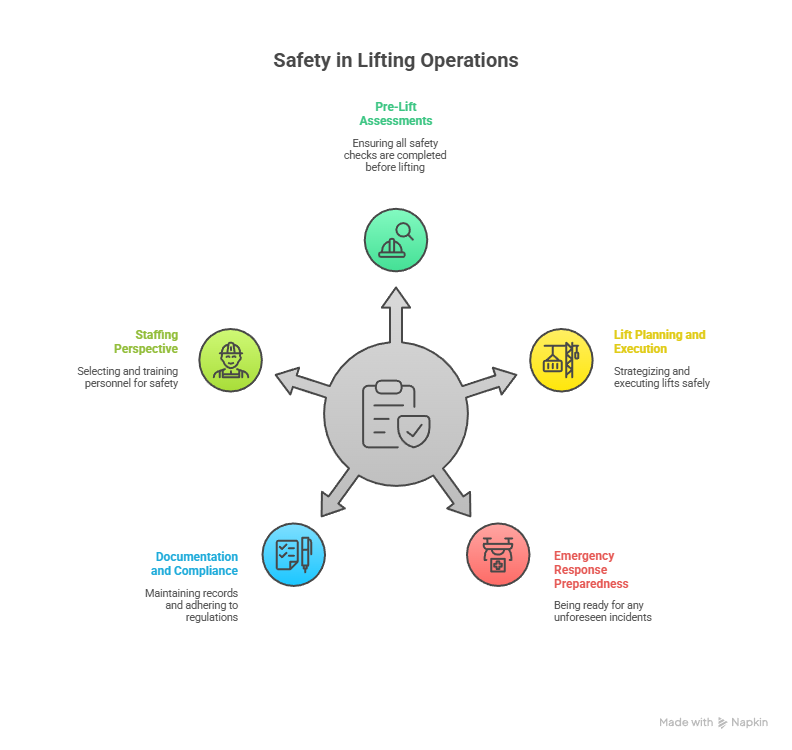

Safety Standards and Risk Management

Crane operations involve some of the most regulated and risk-sensitive activities on a jobsite. Safety performance depends on operator discipline, equipment condition, and alignment with established procedures.

Pre-Lift Assessments

Operators evaluate ground stability, load weight, lift radius, rigging integrity, and environmental conditions before moving any load. They verify that counterweights, outriggers, and boom configurations match the lift plan and equipment specifications.

Lift Planning and Execution

Accurate lift planning determines how the load will move, where personnel must stand, and how communication will be maintained. Operators follow the plan while adjusting for real-time conditions, holding lifts when visibility or site changes present new risks.

Emergency Response Preparedness

Operators are trained to respond quickly to mechanical issues, unexpected load movement, or environmental hazards. Clear communication and immediate action limit the potential for injury or structural impact.

Documentation and Compliance

Operators maintain logs, inspection records, and operation reports that demonstrate adherence to safety guidelines. These records form a compliance layer that employers and staffing teams rely on when auditing jobsite practices.

A staffing perspective integrates safety into workforce selection. Employers expect operators who follow established standards consistently, regardless of the project phase or equipment type.\

Environmental Variables Affecting Crane Operations

Environmental conditions influence every stage of crane work. Wind affects load stability. Temperature impacts hydraulic systems. Rain, snow, and ice alter ground conditions and visibility. Operators must recognize how these factors change the crane’s behavior and determine whether a lift can proceed safely.

Workforce dependability becomes critical during unstable weather windows. Employers prefer operators who understand risk thresholds and maintain disciplined decision-making even when project schedules are tight. Reliable staffing ensures that qualified personnel are available when environmental conditions shift unexpectedly.

Equipment Inspections and Maintenance Awareness

Operators inspect cranes at the start of each shift, verifying that structural components, wire ropes, hydraulic lines, sheaves, and controls are functioning as intended. They evaluate hooks, safety latches, load lines, and indicators for signs of wear or deformation.

When issues arise, operators pause operations and coordinate with maintenance teams. Their ability to identify early equipment concerns protects the jobsite from avoidable incidents. Employers value operators with strong inspection habits, and staffing teams prioritize candidates with a demonstrated understanding of mechanical safety and equipment integrity.

Workforce Expectations for Modern Crane Operators

The labor market for crane operators has tightened as infrastructure expansion, industrial growth, and large-scale development projects increase demand. Employers place high expectations on operator performance because each lift influences the productivity and safety of multiple crews.

Reliable Jobsite Presence

Consistency is a defining requirement. Operators must arrive prepared, maintain uptime, and coordinate with scheduling demands. Delays caused by absenteeism, fatigue, or misalignment of shift expectations disrupt site sequencing.

Staffing reliability mitigates these risks by supplying qualified operators who meet attendance standards and have verified experience relevant to the equipment being used.

Adaptability Across Work Environments

Crane operators move between varied job settings—from commercial construction to refinery operations, ports, energy installations, and heavy manufacturing. Each environment presents unique lift requirements, equipment layouts, and hazard profiles.

Employers seek operators who maintain composure under differing site conditions. Staffing processes help ensure that workers placed in specialized environments have relevant background experience and the temperament needed for high-pressure lifts.

Professional Accountability

Operators are expected to communicate accurately, follow protocols, and treat each lift as a technical procedure. Professional conduct includes respect for site hierarchy, adherence to safety briefings, and proactive communication when conditions change.

A staffing-integrated framework recognizes accountability as a top hiring factor. Companies want operators who consistently execute their responsibilities without requiring corrective oversight.

The Importance of Matching Operators to Project Requirements

Not all crane operators are interchangeable. Equipment type, lift complexity, project phase, and site conditions determine which operators are qualified for specific assignments.

Equipment-Specific Expertise

An operator trained on mobile cranes may not be prepared for tower crane work involving greater height, longer radii, and complex visibility challenges. Similarly, overhead crane operators require familiarity with indoor industrial environments rather than outdoor construction dynamics.

Matching operators to equipment reduces risk and increases operational efficiency. Staffing teams evaluate operator histories to ensure each candidate’s experience aligns with client needs.

Project-Specific Demands

Some projects require operators who understand steel erection sequencing, while others depend on operators skilled in modular placement, concrete bucket operations, or heavy industrial lifts.

Employers gain significant value from staffing partners who understand these nuances and place operators based on proven capability rather than broad classification.

Experience with Jobsite Coordination

Advanced lifts involve multiple trades, engineered lift plans, and tight timelines. Operators experienced in coordinated work environments maintain smoother communication with riggers, foremen, and site supervisors.

Workforce placement benefits when staffing providers evaluate interpersonal skills and prior collaborative job history, not only equipment proficiency.

How Workforce Stability Impacts Project Outcomes

The availability of qualified crane operators influences a project’s timeline, cost management, and safety performance. Workforce stability ensures that cranes operate when needed and that lifts are performed by individuals with consistent experience.

Schedule Continuity

Cranes often serve as the pacing mechanism for structural progress. When an operator is absent or not adequately trained for the day’s lift plan, the delay creates costly disruptions.

Stable staffing ensures that each lift occurs as scheduled, allowing other trades to progress without interruption.

Reduced Rework and Material Damage

Operator precision determines whether material is placed correctly the first time. Skilled lifts prevent damage to structural components, prefabricated modules, and sensitive materials.

Employers depend on consistent operator quality, and staffing alignment helps maintain that standard across the full duration of the project.

Improved Safety Culture

A reliable operator workforce reinforces safety expectations across the site. Consistency in behavior, communication style, and lift discipline reduces the likelihood of avoidable incidents.

When staffing providers verify certification, evaluate safety records, and prioritize experienced operators, employers benefit from a stronger safety culture supported by dependable personnel.

How Employers Evaluate Crane Operator Candidates

Hiring managers assess more than certification status. They examine technical capability, consistency, decision-making, and communication skills to determine whether an operator fits the demands of a given project.

Practical Experience and Equipment Hours

Hands-on hours offer insight into whether the operator has managed lifts similar to those required on the job. Employers prefer operators who demonstrate experience across multiple scenarios rather than those limited to basic functions.

Safety Record and Incident History

A clean safety record reflects disciplined lift execution and situational awareness. Employers consider previous incident reports, near-miss documentation, and patterns of behavior.

Staffing teams help validate these records and ensure accuracy before placement.

References and Work Reliability

Past supervisors offer insight into an operator’s dependability, communication style, and adaptability. Employers often request operators who have previously demonstrated stability and teamwork.

Staffing providers streamline this process by maintaining verified operator profiles.

Certification and Documentation Accuracy

Employers require complete documentation for compliance. Missing or outdated certificates create liability exposure.

Staffing systems help manage document tracking so that operators assigned to a site arrive fully credentialed.

Crane Operator Specializations That Influence Placement

Certain crane operators develop specialty skills that qualify them for advanced lifts or niche industry sectors. These skills affect placement decisions and project performance.

Heavy Lift Specialists

Some operators handle oversized or exceptionally heavy loads, often working with multi-crane lifts or engineered lift plans. These roles require advanced judgment and strong familiarity with load moment behavior.

Industrial and Manufacturing Operators

Operators in controlled indoor environments manage repetitive material movement with a focus on efficiency and precision. Their work differs significantly from construction settings and demands familiarity with production workflows.

Port and Marine Operators

Port operators move shipping containers, bulk materials, and heavy cargo in areas where timing, coordination, and environmental influence play central roles.

Energy Sector Operators

Wind, oil, gas, and utility projects require operators who understand terrain challenges, weather impacts, and the specialized equipment used for turbine components, pipeline segments, or substation structures.

Specialized operators command a higher operational impact and must be matched meticulously to employer requirements. Staffing perspectives help ensure proper alignment.

The Role of Technology in Modern Crane Operation

Advancements in crane technology continue to shift operator responsibilities. Digital tools assist with lift accuracy, diagnostics, and operational visibility, requiring operators to develop new proficiencies.

Load Indicators and Digital Sensors

Modern cranes incorporate sensors that measure boom angle, load weight, radius, and structural stress in real time. Operators interpret these systems to maintain safe lift parameters.

Telematics and Performance Monitoring

Telematics systems track crane usage, maintenance intervals, and operational patterns. Employers rely on this data to evaluate equipment performance and operator behavior.

Staffing teams consider these insights when confirming operator effectiveness on long-term projects.

Remote Operation and Assist Controls

Emerging remote-control options allow operators to stand outside the cab during specific lifts, improving visibility. Automated assist functions help stabilize loads or prevent unsafe operation conditions.

Operators must adapt to these technologies while maintaining traditional mechanical awareness.

Communication and Visibility Enhancements

Cameras, audio systems, and digital communication tools improve coordination between operators and riggers. Operators trained on modern systems have an advantage when working on complex lifts.

A staffing-aware approach recognizes this technological competency as a placement differentiator.

The Growing Demand for Qualified Crane Operators

Industries that depend on cranes continue expanding as infrastructure investment, industrial development, and large-scale construction rise. Operators with verified experience remain essential to keeping these projects moving.

Infrastructure and Public Works

Highway reconstruction, bridge development, rail expansion, and water treatment upgrades rely on cranes for heavy material placement. Operators who understand complex staging environments are in consistent demand.

Renewable Energy Growth

Wind turbine installation, solar field construction, and energy storage facilities require specialized lifting operations for large components. Operators familiar with heavy, tall, or unstable loads play a crucial role.

Manufacturing and Industrial Expansion

Distribution centers, logistics hubs, processing plants, and heavy manufacturing facilities depend on overhead cranes and indoor lifting operations. Operators with industrial experience remain in steady demand.

Commercial and Residential Construction

Multistory buildings, mixed-use developments, and large residential complexes rely on tower cranes and mobile cranes for structural placement. Skilled operators help maintain building progress and sequencing.

These expanding sectors elevate the importance of staffing systems that can supply qualified operators on schedule without compromising safety or technical precision.

Temporary, Project-Based, and Long-Term Operator Needs

Companies rely on different staffing models depending on project type, duration, and operational complexity. Crane operators support jobs ranging from a single set-and-go lift to multi-year industrial expansions.

Temporary and Short-Duration Assignments

Short-term projects often require operators for precise, time-limited lifts such as equipment placement, HVAC installation, steel delivery, or modular positioning. Employers need operators who can arrive fully prepared, understand the lift plan quickly, and perform without extended onboarding.

Staffing flexibility helps companies secure operators on short notice, especially when scheduling changes or unexpected workforce gaps arise.

Project-Based Staffing

Large construction and industrial projects demand operators for weeks or months. Their role evolves as project phases shift from foundation work to structural assembly to finishing lifts.

Consistency in staffing ensures operators remain familiar with the jobsite, understand communication patterns, and sustain safe lift performance through each stage.

Long-Term Workforce Needs

Facilities with overhead or gantry cranes often employ operators continuously to support materials handling and production cycles. These roles require dependable professionals who integrate into facility workflows and maintain consistent operating habits.

A staffing-aware perspective recognizes the importance of long-term placements that align operator experience with a facility’s operational rhythm.

How Workforce Providers Support Crane Operations

While the article maintains a broad industry view, a workforce-aware approach acknowledges the operational significance of dependable staffing. Workforce partners play a critical role in supporting crane operations without functioning as a direct promotional element.

Credential Verification

Staffing teams ensure operators are certified, current on training, and compliant with employer requirements. This reduces administrative burden for jobsite supervisors.

Skill Matching and Lift-Specific Pairing

Operators are matched based on their equipment history, lift experience, and familiarity with relevant jobsite conditions. This helps employers avoid mismatches that slow productivity.

Availability and Scheduling Support

When operators are needed for rapid deployment or schedule changes, staffing providers secure qualified personnel who meet the necessary standards.

Safety Alignment

Workforce partners prioritize candidates with strong safety records and consistent adherence to lift protocols. This supports a safer, more predictable jobsite environment.

Workforce Continuity

Longer projects require consistent operator availability. Staffing systems maintain coverage so employers do not experience delays due to personnel gaps.

People Also Ask — Crane Operators FAQ

What does a crane operator do?

A crane operator controls heavy lifting equipment used to move and position materials on construction sites, industrial facilities, ports, and energy projects. Their work requires precision, strong communication, and strict adherence to safety procedures.

How do you become a crane operator?

Operators complete formal training, gain supervised practical experience, and earn certification through recognized assessments. Additional training may be required based on crane type and jobsite environment.

What skills are important for crane operators?

Operators need mechanical understanding, steady control, situational awareness, communication ability, and disciplined judgment. These skills ensure safe and accurate lifts.

Are crane operators in demand?

Industries that rely on heavy lifting—such as construction, infrastructure, manufacturing, and energy—consistently need qualified operators. Workforce shortages increase demand for certified professionals.

What are the biggest safety concerns for crane operators?

Key concerns include load stability, weather conditions, rigging integrity, ground conditions, and clear communication. Maintaining awareness of these factors prevents incidents.

Do crane operators need certification?

Most crane roles require operators to hold nationally recognized certification. Employers rely on certification to verify competency and meet compliance requirements.

Where do crane operators work?

Operators work in construction sites, industrial plants, ports, warehouses, refineries, energy facilities, and infrastructure projects. Each environment requires different lift practices.

How do employers find qualified crane operators?

Employers evaluate certification, lift experience, safety records, and equipment familiarity. Many rely on staffing partners to secure qualified operators who meet project requirements.